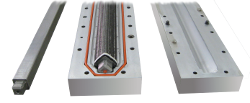

Resin Transfer Molding

Resin Transfer Molding is an infusion process by which the matrix resin is transfered via pump into a matched tool that contains a preform.

BENEFITS:

- High toleranced dimensional capability with matched metal tooling.

- Superior surface finish.

- High production rate capability.

- Near net shape, lower post mold processing needed.

- Highest repeatability, lowest variability for product & process characteristics.

CHALLENGES:

- Higher tooling costs.

- Higher NRE costs.

- Longer tooling lead time.