Molding Processes

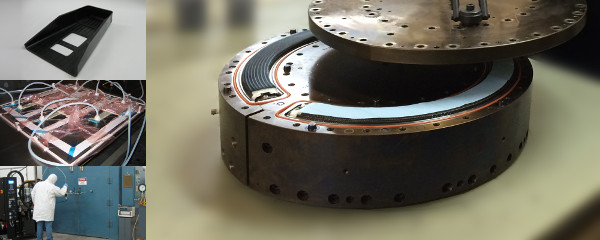

Resin Transfer Molding (RTM) is an infusion process wherein the matrix resin is injected using a combination of vacuum and pressure into a dry fiber preform located in a closed cavity mold. The RTM process offers the ability to achieve dimensional control on all surfaces as parts are formed using matched inner and outer tooling. Tools are CNC machined to high tolerances, so the molded surfaces can be complex in shape and very precise. The RTM process is the ideal choice for repeatable production of high tolerance composite structures with low void content requirements and average fiber volume fractions of 55% - 60%.

BENEFITS:

- High toleranced dimensional capability with matched metal tooling.

- Superior surface finish.

- High production rate capability.

- Near net shape, lower post mold processing needed.

- Highest repeatability, lowest variability for product & process characteristics.

CHALLENGES:

- Higher tooling costs.

- Higher NRE costs.

- Longer tooling lead time.

Vacuum Assisted Resin Transfer Molding is an infusion process that utilizes single sided tooling and consumable vacuum bagging materials to transfer the matrix resin from a holding vessel at ambient atmospheric pressure into the preform which is under vacuum pressure.

This process is beneficial for customers that have less stringent dimensional and surface asthetic requirements. One side is high quality tooling controlled while the other is bag surface (rough, fabric like texture).

BENEFITS:

- Lower cost, single sided tooling.

- Faster tooling aquisition time.

- High dimensional tolerance on tooled surface.

- Possible to use cauling to improve bag side dimensions.

- Mature, proven process with high quality results.

CHALLENGES:

- Requires highly skilled technicians.

- Increased post molding opertions.

- Higher recurring costs for consumables.

- Longer process cycles.

Revolution Composites processes many composite matrix resin types. Thermosets, Thermoplastics, and Ceramics are the main classifications of composite matrixes. The Revolution Composites team is experienced in manufacturing quality products using most of these materials.

These high performance materials are best suited for specific end use applications. Contact us to discover the best matrix for your next product.

Thermoset Resins:

- Epoxies

- Bismaleimides (BMI's)

- Cyanate Esters

- Polyesters

- Vinyl Esters

- Phenolics

Thermoplastic Resins:

- PEEK

- PPS

- PBT

- Nylon

- Polycarbonate