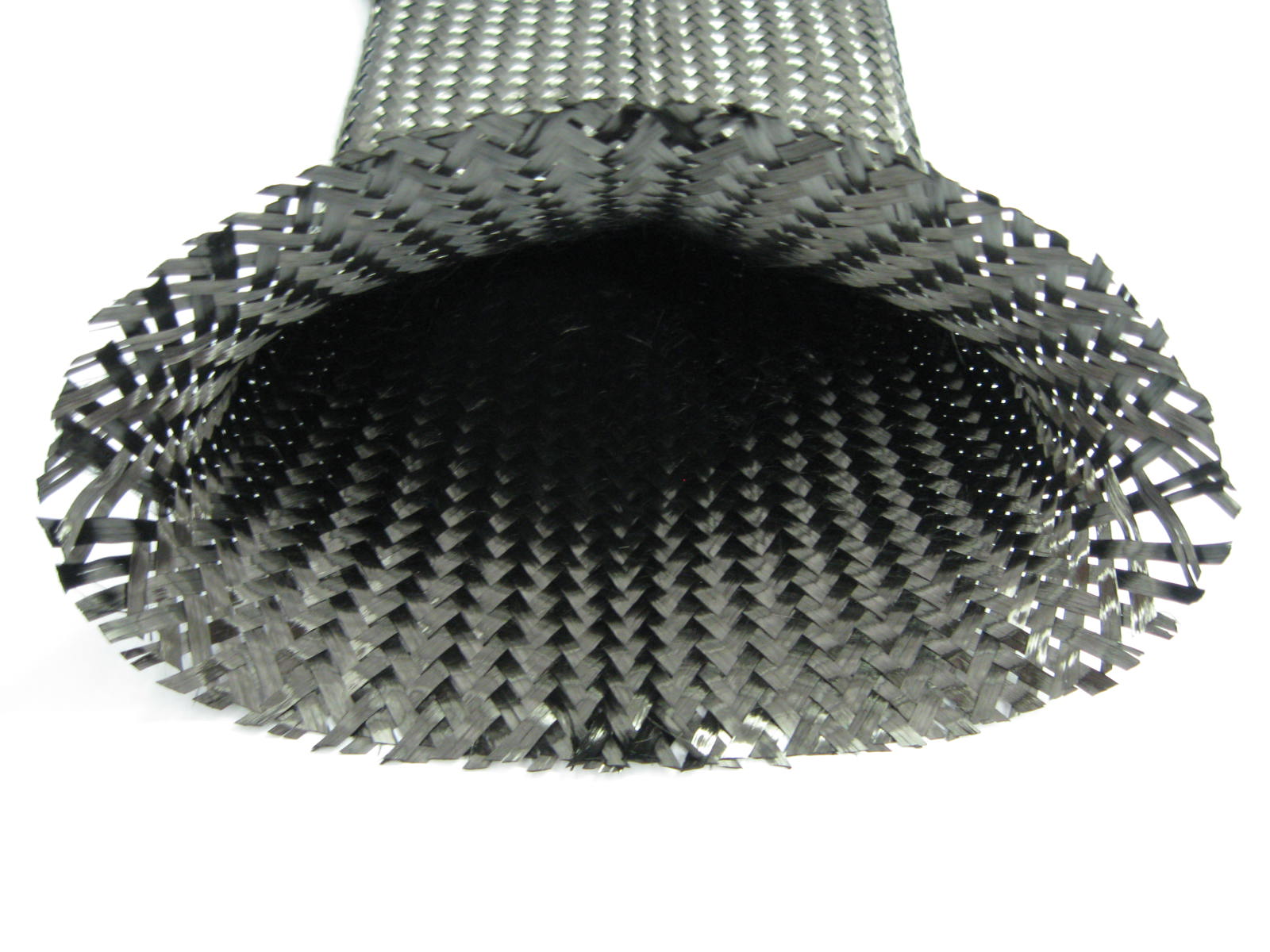

Vacuum Assisted Resin Transfer Molding is an infusion process that utilizes single sided tooling and consumable vacuum bagging materials to transfer the matrix resin from a holding vessel at ambient atmospheric pressure into the preform which is under vacuum pressure.

This process is beneficial for customers that have less stringent dimensional and surface asthetic requirements. One side is high quality tooling controlled while the other is bag surface (rough, fabric like texture).

BENEFITS:

- Lower cost, single sided tooling.

- Faster tooling aquisition time.

- High dimensional tolerance on tooled surface.

- Possible to use cauling to improve bag side dimensions.

- Mature, proven process with high quality results.

CHALLENGES:

- Requires highly skilled technicians.

- Increased post molding opertions.

- Higher recurring costs for consumables.

- Longer process cycles.