Hand Lay Up is a preforming process that uses fabrics that are cut to the desired shape to build up the parts cross section using layers or plys. This allows us to tailor the reinforcements to provide maximum material properties of the final part.

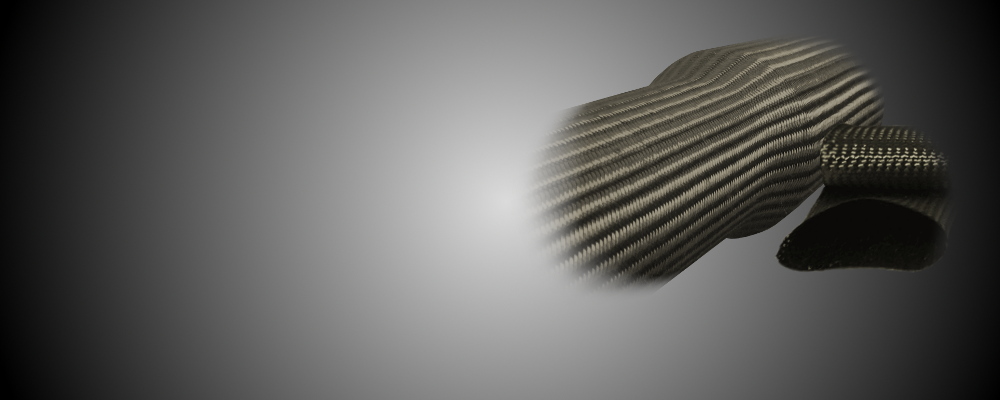

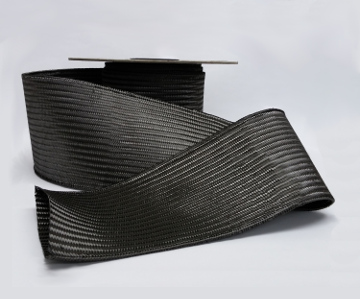

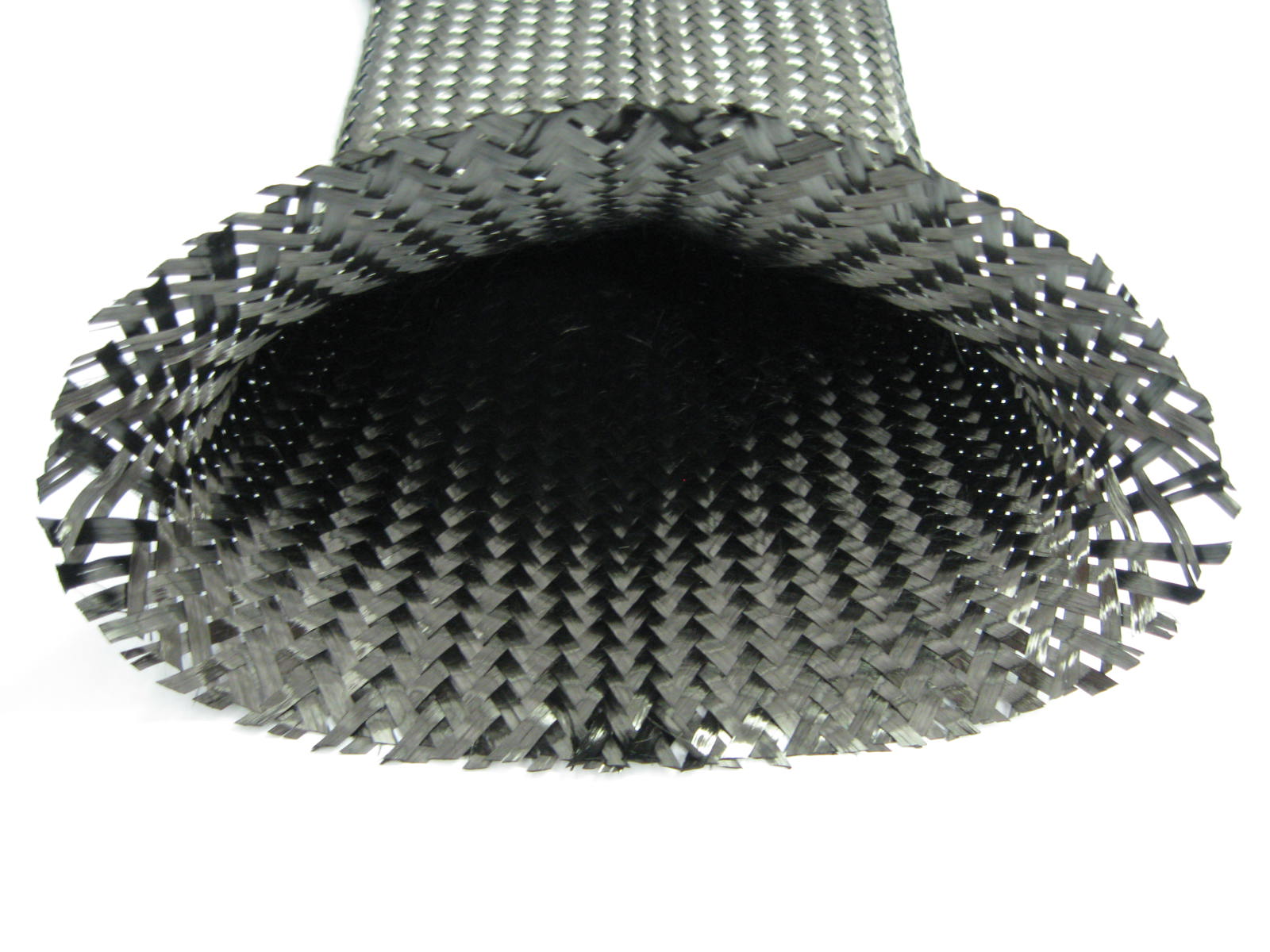

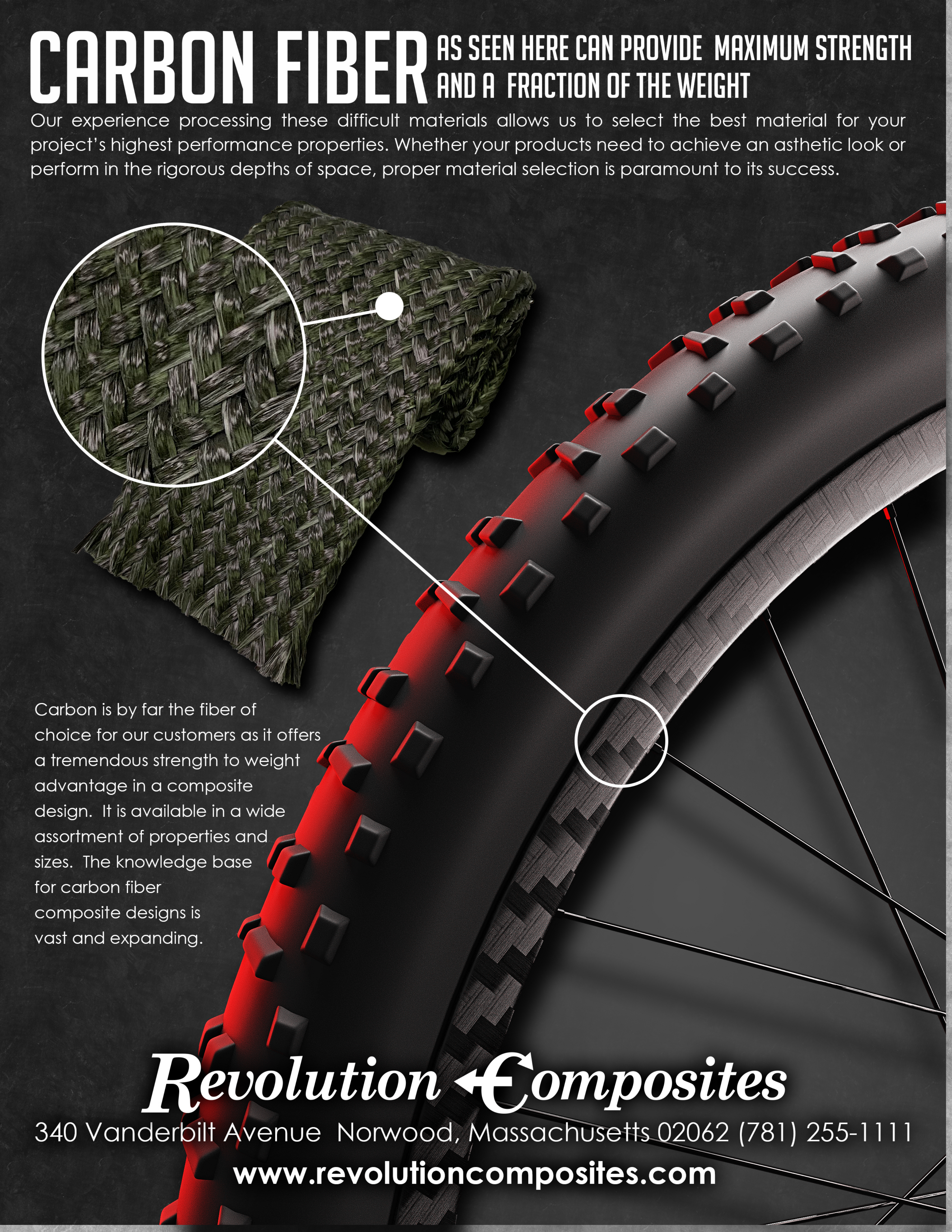

The reinforcing fabrics can be braided, woven, stitched uni-fabrics and surfacing veils. The fabrics can be comprised of aramibs, carbons, glass, ceramics, or any combination required to yield the desired final proprties.

The layers or plys are precisely trimmed to shape using templates or cnc controlled cutters and are located onto tooling using tooling features, fixtures, jigs, templates, or laser positioning devices.

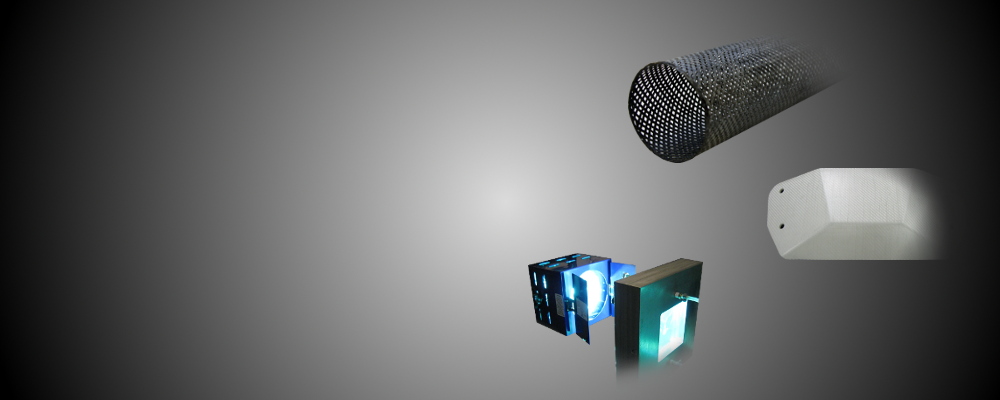

The resulting preform can be debulked, trimmed and placed in a mold and infused to create a composite part, or it can be used as a feature or buildup in another preform. This is a typical application in our braided parts which allows faster cycle times for complex shapes and through thickness variations to achieve product performance requirements such as localized stress relief.